After a remodel of the staff lounge for the Architecture Department I was asked to design and construct a new staff mailbox. The design was based on an abstraction of a building facade. Knowing it would be used by fellow designers I wanted it to be functional but also visually interesting.

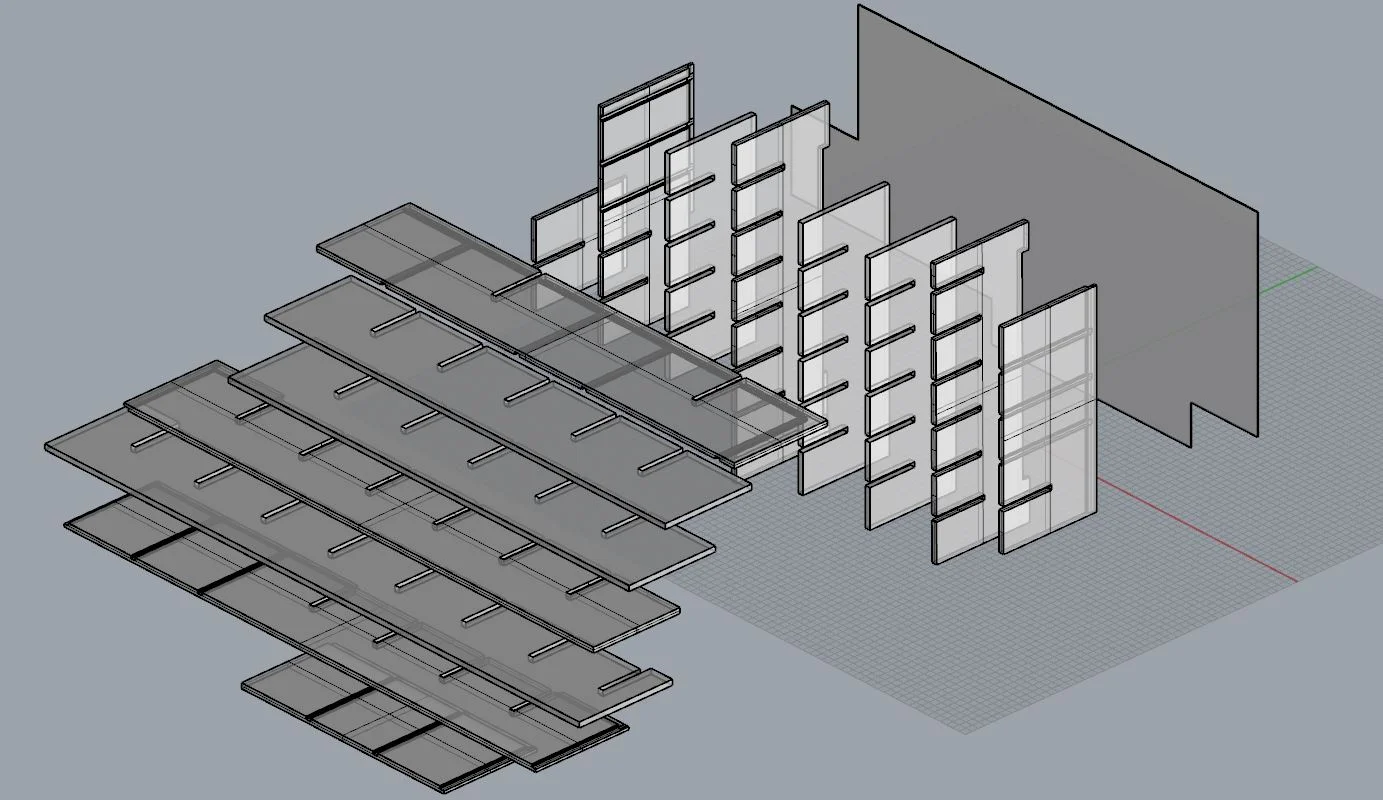

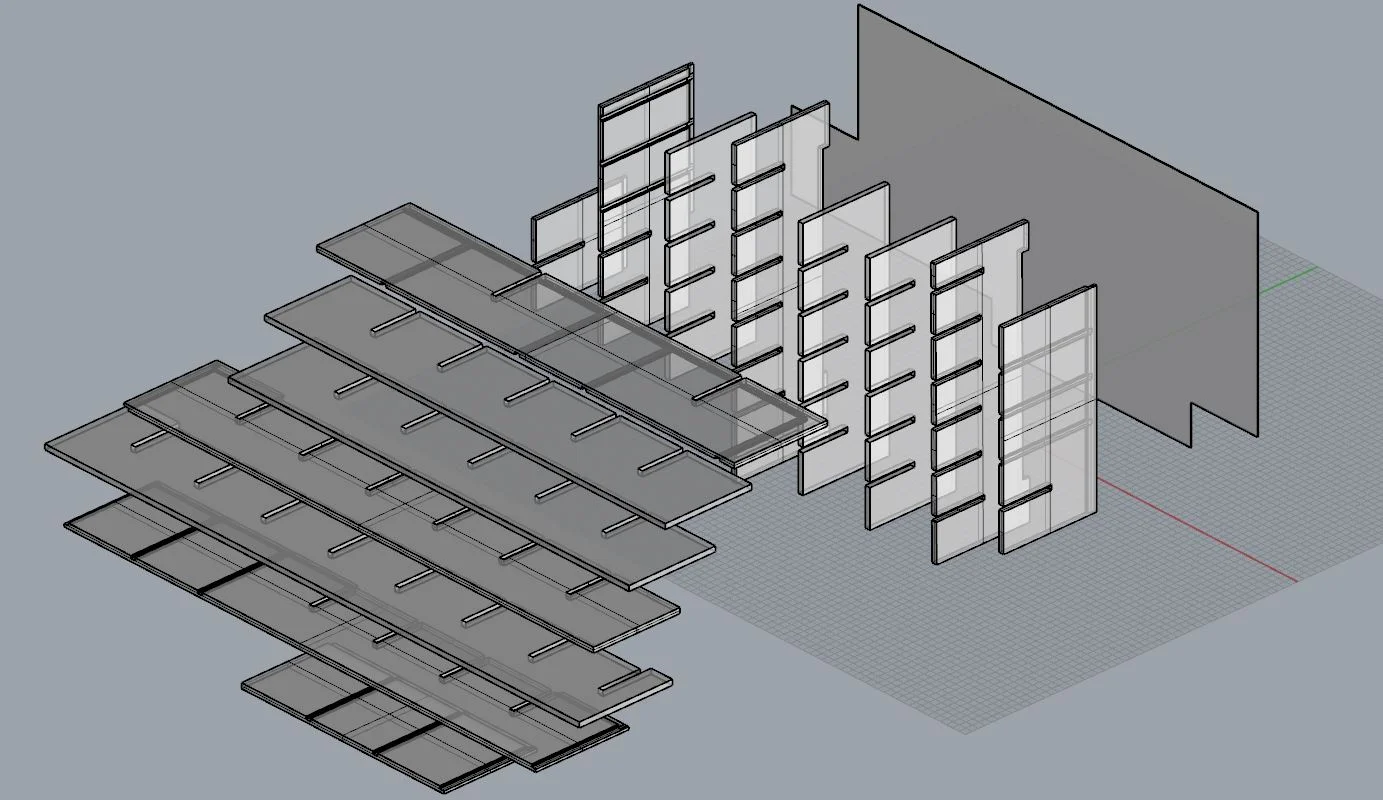

This was really my first CNC project so I wanted to make sure I got it right. I obsessed over drawings and digital models to be sure all of the joints and junctions were spot on and it would be well made.

I based the mailbox size on the standard 9x12 document envelope that gets used in a lot of communications between departments on campus.

I noticed with the previous mailbox that the name labels were haphazard and many of them had been simply taped on. I focused on how to make name plates that fit with the design aesthetic but could be easily moved to accommodate changes in staff.

Using the in house laser cutter I etched and cut out each individual name in basswood, epoxyed rare earth magnets to the back, and counter sunk screws for the plates to attach to. The system works great and the magnets give the name plates a satsifying snap into place.